Door Jambs

A pre-hung door consists of a door hung on hinges and assembled in a wood frame (the frame is also called the door “jamb”), with a door stop. A pre-hung door is ready to install in the door opening, with no on-site assembly required. This reduces construction time and scheduling, and lowers project cost. If the pre-hung door is also pre-finished, this further reduces steps and cost in the construction process.

Sun Mountain not only manufactures the highest quality doors, but also offers optional pre-hanging of the doors. Factory pre-hanging ensures that hinge pockets are mortised square and precise, and that hinges are always flush on the door and frame. Hinges are included in the price of pre-hanging, and are available in a selection of metal finishes. Machining for hardware (boring and latch/deadbolt mortising for handles and locksets) is also provided at no additional cost with factory pre-hanging. A choice of single or double bore options is available in different “backset” positions (the placement of the handle or lockset from the door edge). Factory pre-hanging also ensures that the “reveal” (the small gap between the door and the jamb, when the door is closed) is always correct. Sun Mountain’s standard pre-hanging options are shown here. Custom door jambs, including unique designs and sizes, are also available upon request. Contact Sun Mountain at 888.786.6861 or sales@sunmountaindoor.com to request a free, no obligation quote.

To learn about Sun Mountain’s standard pre-hanging options and choices, click the links below:

Jambs for Interior Doors

Jambs for Exterior Doors

Jamb Widths

Handing and Swing

Machining for Hardware

Hinges

Shipping Pre-Hung Doors

Jambs for Interior Doors

FLAT JAMBS WITH ADJUSTABLE STOP

For interior doors, Sun Mountain offers solid wood flat jambs with an adjustable stop. If the door is ordered with a factory-applied wood finish, the jambs and stop are finished separately. This provides for installation of the jamb and on-site adjustment of the stop without finish touch-up.

KERFED FLAT JAMBS

Sun Mountain also offers solid wood “kerfed” flat jambs. A kerf is a slot cut on the edge of the jamb, used for wrapping the drywall corner bead (square or rounded drywall corners) into the jamb. Kerfed flat jambs provide for a “caseless” opening, with drywall connecting directly to the door frame, thus requiring no case mouldings. Kerfs can be on both sides (as shown) or on just one side of the jamb.

If Sun Mountain finishes a pre-hung interior door in the factory, the door jamb is also finished at no additional cost. The adjustable stop is finished separately from the jamb, providing for on-site adjustment without touch-up.

Jambs for Exterior Doors

RABBETED JAMBS

Pre-hanging of exterior doors is much more expensive than pre-hanging interior doors. First, exterior doors are framed with a more robust rabbeted jamb. A rabbeted jamb includes a non-adjustable stop cut into solid wood, and Q-Lon® weatherstrip that is inserted into a kerf (or slot) cut into the stop of the jamb. Weatherstrip is a durable foam rubber material used to seal the side and top edges of an exterior door, to limit air transfer and exposure to outside elements.

KERFED RABBETED JAMBS

Sun Mountain also offers solid wood kerfed rabbeted jambs. If this application is desired, exterior doors are normally kerfed on only one side—the inside—of the door (as shown).

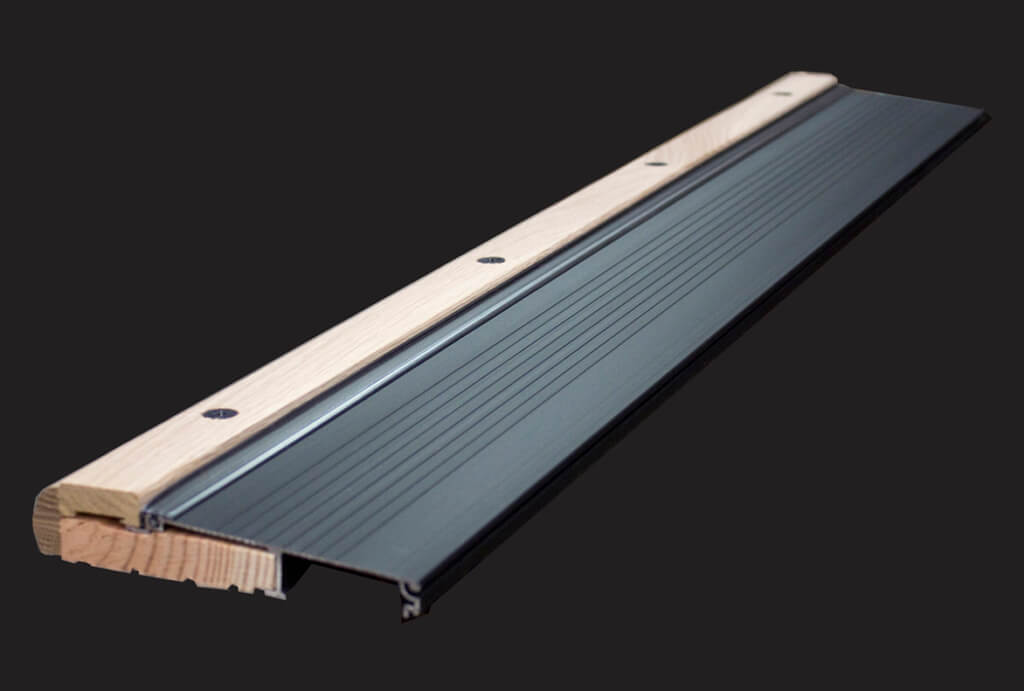

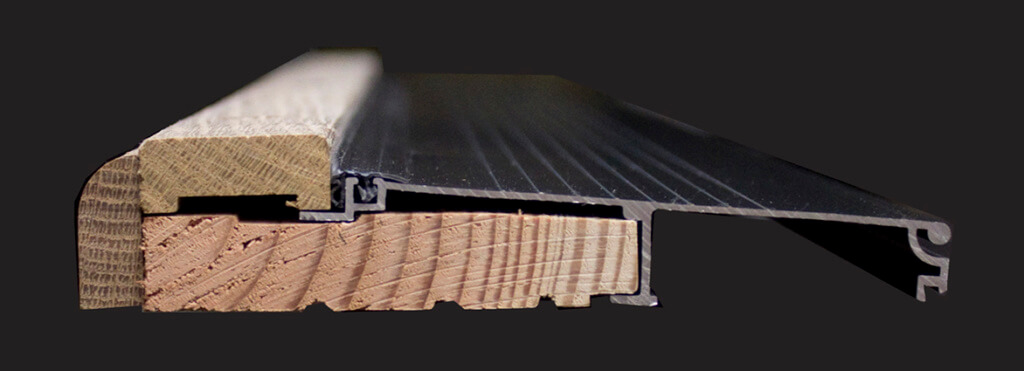

SILLS

Sun Mountain’s pre-hung exterior doors also include an aluminum adjustable door sill—a metal threshold at the bottom of the entry unit. This standard sill is available in either Mill (aluminum) color or Oil Rubbed Bronze color, with either inswing or outswing options, and is included in the price of the exterior pre-hanging.

Other sill options are also available for exterior doors including ADA sills, wood sills, hydro sills (recommended for double doors; an additional price applies), etc.

SWEEPS

Sun Mountain provides either L-shaped or surface mount door sweeps standard with factory pre-hung exterior doors. These sweeps include a drip cap to direct water away from the door. L-shaped sweeps are provided on all 1-3/4″ thick exterior doors. Surface mount sweeps are provided on all 2-1/4″ thick or thicker exterior doors. If shipped separately and installed on-site, Sun Mountain recommends sealing the top edge of the sweep with a bead of silicone at time of installation, to prevent moisture from seeping between the sweep and the door.

BRICK MOULDING

If desired, pre-hung exterior doors can include 2″ wide x 1-1/16″ thick brick case moulding for the exterior side of the door, at no additional cost (excluding radius brick moulding). The standard brick mould has an eased edge on the top surface corners of the moulding (called “eased 2 edges,” or E2E). Other decorative profiles and stucco moulding are also available, at no additional cost (excluding radius profiles and stucco moulding).

If Sun Mountain finishes a pre-hung exterior door in the factory, the rabbeted jamb and brick mould are also finished at no additional cost.

JAMB WIDTHS

Door jambs must cover the entire thickness of the wall where the door will be placed. Wall thickness includes the wall stud plus the sheetrock thickness. Normally, either 2×4 or 2×6 studs are used for wall framing. Sheetrock is usually either 1/2″ thick or 5/8″ thick (premium sheetrock). Determine the wall stud and sheetrock thickness and then use the charts below to select the proper jamb width to match the application.

INTERIOR JAMB WIDTHS

Flat interior door jambs are available in the following widths, to match the following wall stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 4-5/8″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 4-7/8″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 6-5/8″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 6-7/8″ Wide |

Kerfed (both sides) flat jambs for interior doors are available in the following widths, to match the following wall stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 3-1/2″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 3-1/2″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 5-1/2″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 5-1/2″ Wide |

Kerfed (one side) flat jambs for interior doors are available in the following widths, to match the following wall stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 4-1/16″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 4-3/16″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 6-1/16″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 6-3/16″ Wide |

EXTERIOR JAMB WIDTHS

Rabbeted jambs for exterior doors are available in the following widths, to match the following wall stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 4-5/8″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 4-7/8″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 6-5/8″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 6-7/8″ Wide |

Kerfed (one side) rabbeted jambs for exterior doors are available in the following widths, to match the following stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 4-1/16″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 4-3/16″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 6-1/16″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 6-3/16″ Wide |

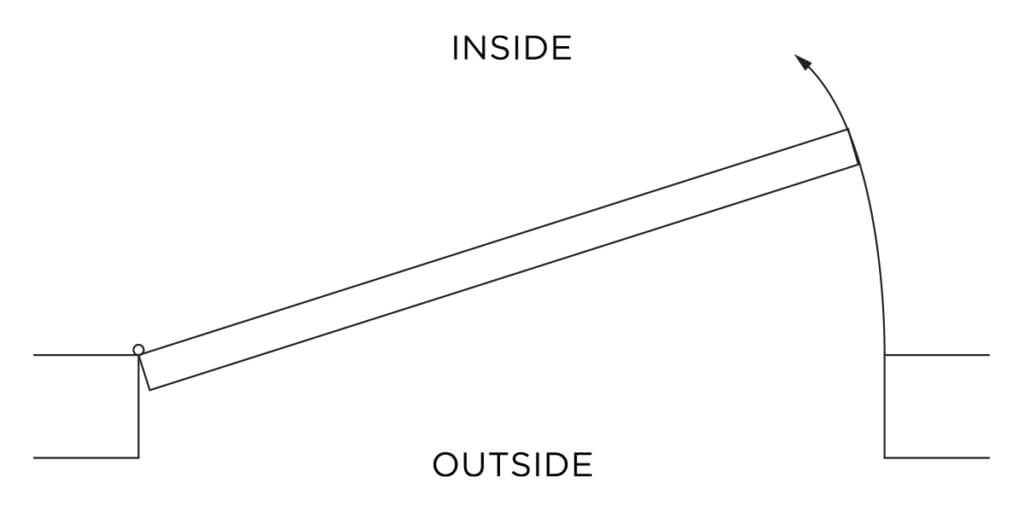

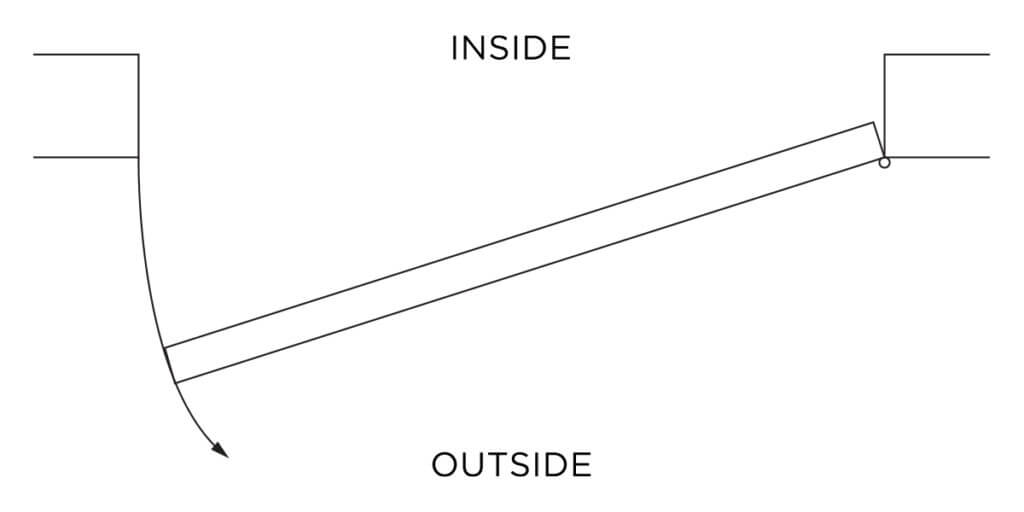

HANDING AND SWING

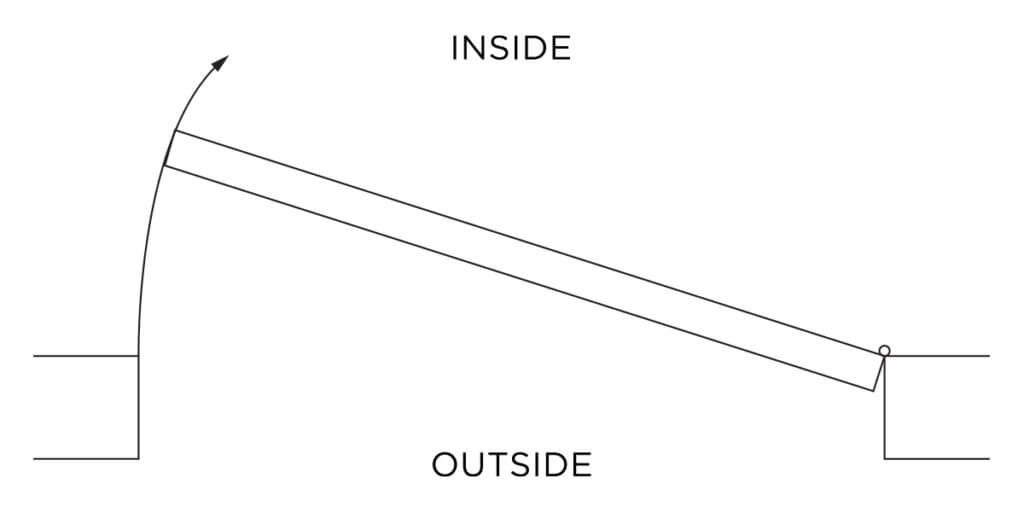

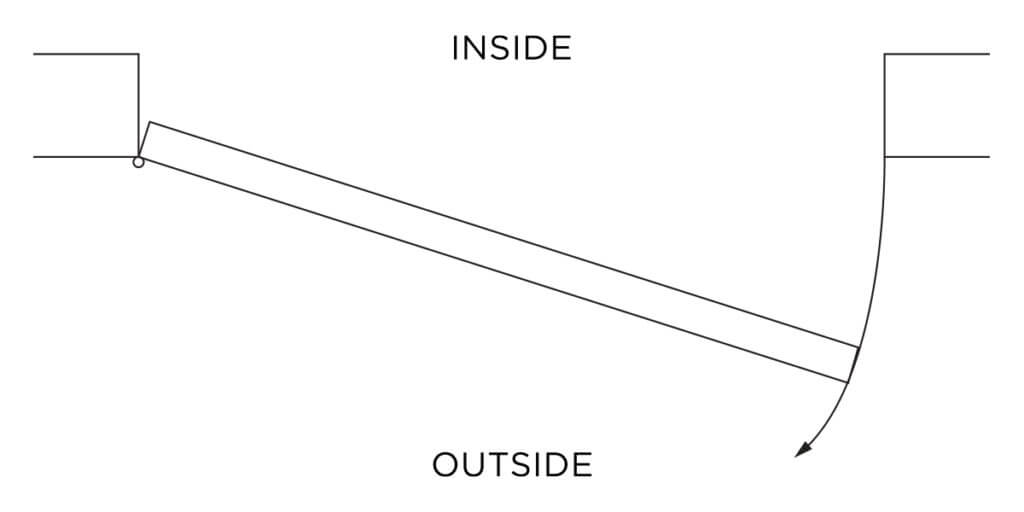

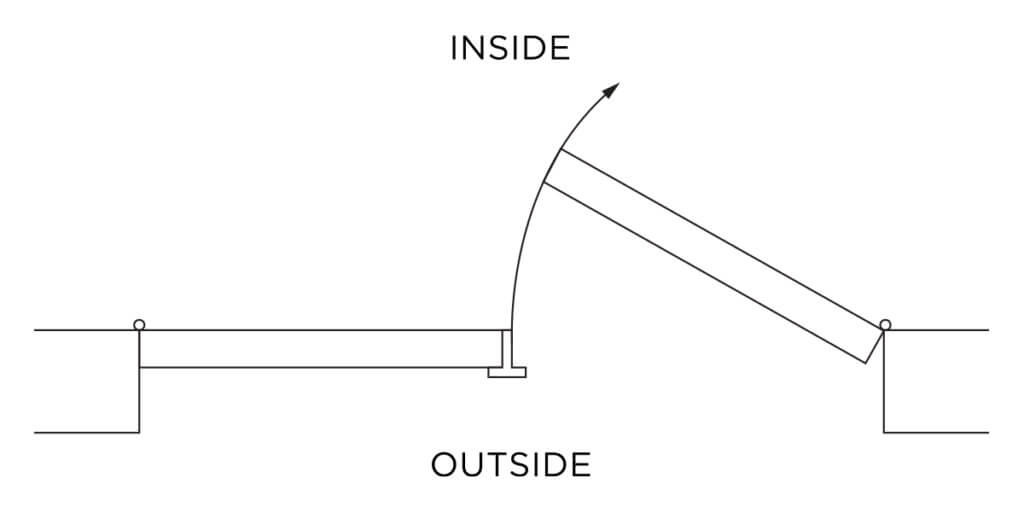

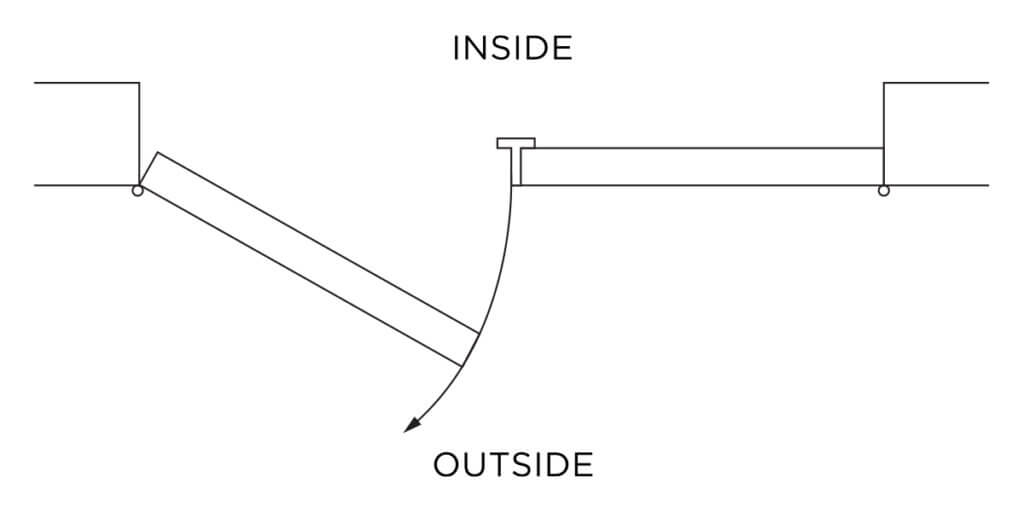

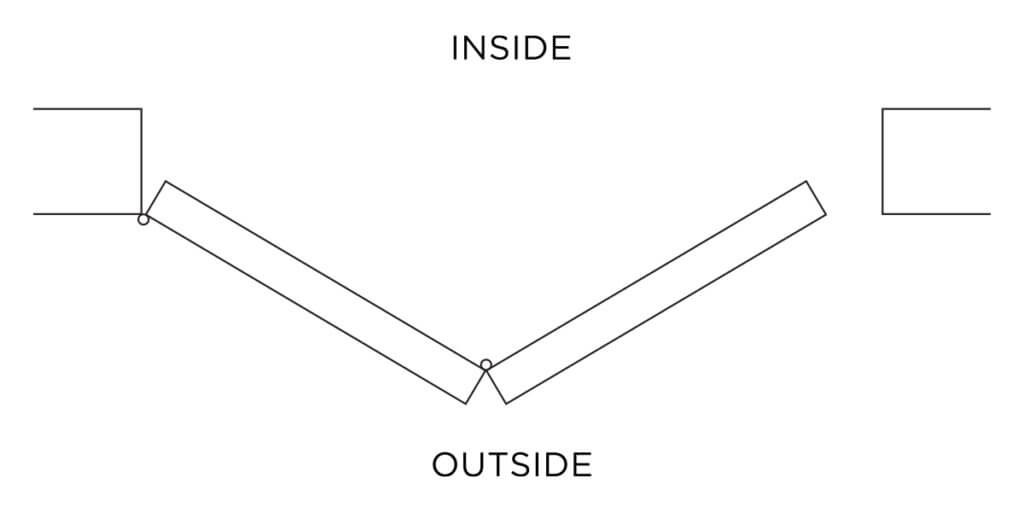

“Handing and swing” refers to way the door opens—the side of the door that is hinged, and the way the door swings inside or outside of the room or home.

To determine door handing, a person stands in the doorway and positions his or her back against the jamb of the door where the hinges are to be placed. From this position, if the door is desired to open to the left, it is a “left hand” door. Or, from this position, if the door is desired to open to the right, it is a “right hand” door.

If the door is desired to swing inside the room or home, it is an “inswing” door. Or, if the door is desired to swing outside the room or home, it is an “outswing” door.

SINGLE DOORS

The following images illustrate handing and swing for single doors, either interior or exterior doors. Arrows point either inside (inswing) or outside (outswing) of the room or home, as denoted.

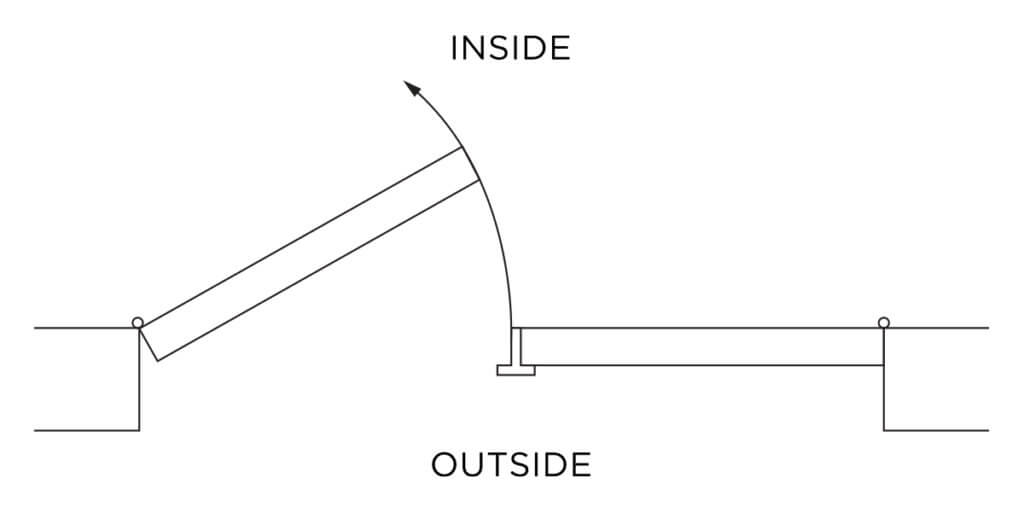

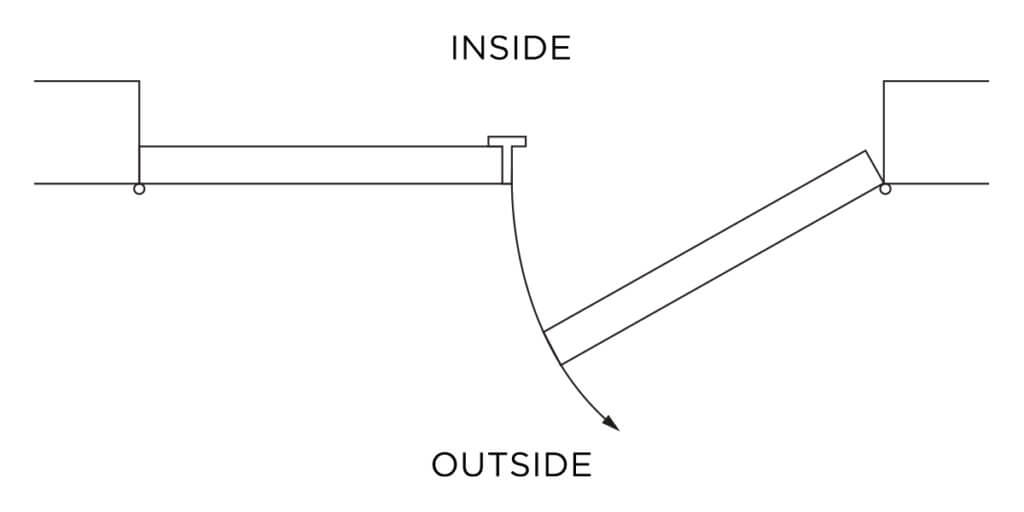

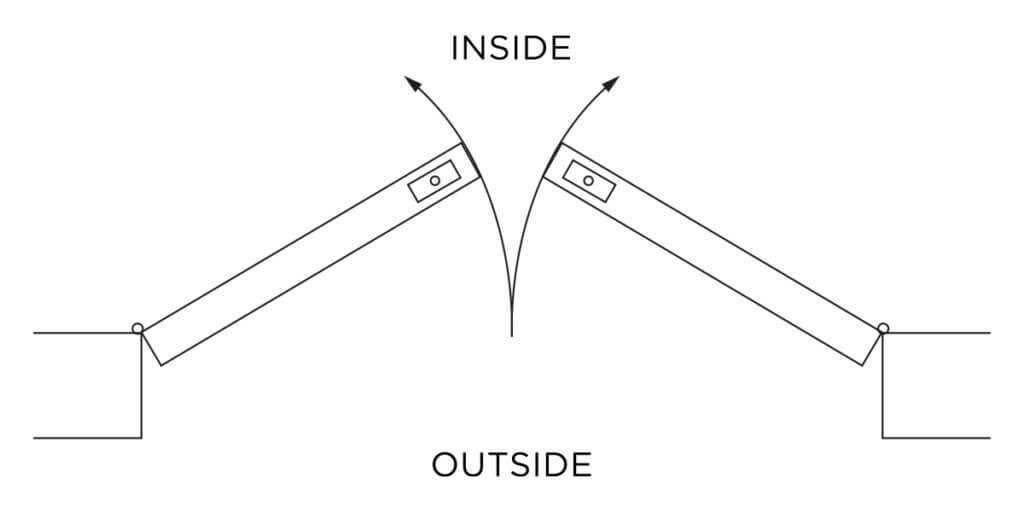

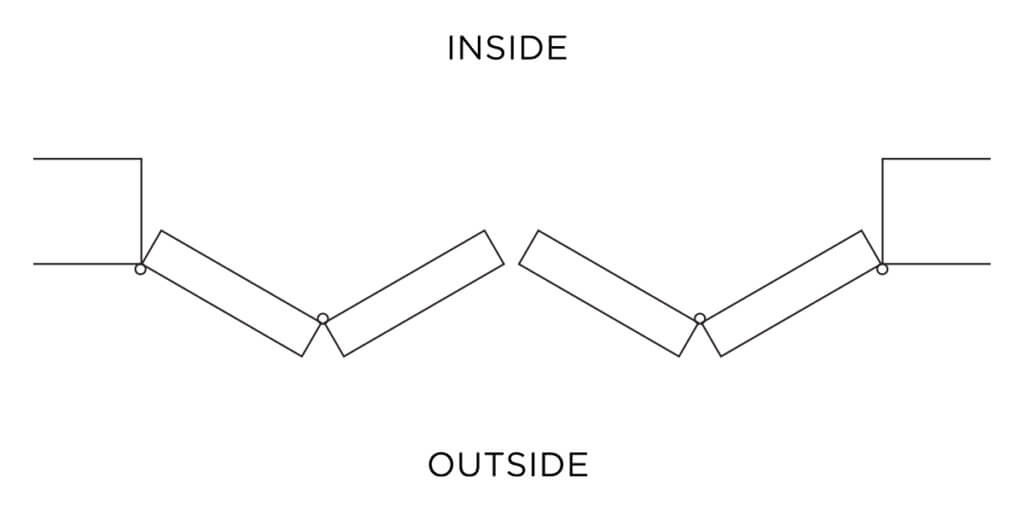

DOUBLE DOORS

For interior or exterior double doors, one door is designated as “active” (i.e., with an operating handle, knob, or lever to open the door), and the other door is designated as “inactive” (i.e., still opens and closes, but with no working handle, knob, or lever). The inactive door includes an attached “T-astragal,” providing a door stop for the active door. The inactive door also includes a “flush bolt,” to secure the inactive door in the closed position. Pre-hung interior double doors include a single flush bolt at the top of the inactive door. Pre-hung exterior double doors include flush bolts at both top and bottom of the inactive door. Sun Mountain provides an extended top flush bolt standard on all 7′ 0″ or higher pre-hung double doors, either interior or exterior. This system lowers the flush bolt latch to a reasonable height, for easier operation.

The following images illustrate the side of the double door that is active, and the active door’s handing and swing. Arrows point either inside (inswing) or outside (outswing) of the room or home, as denoted.

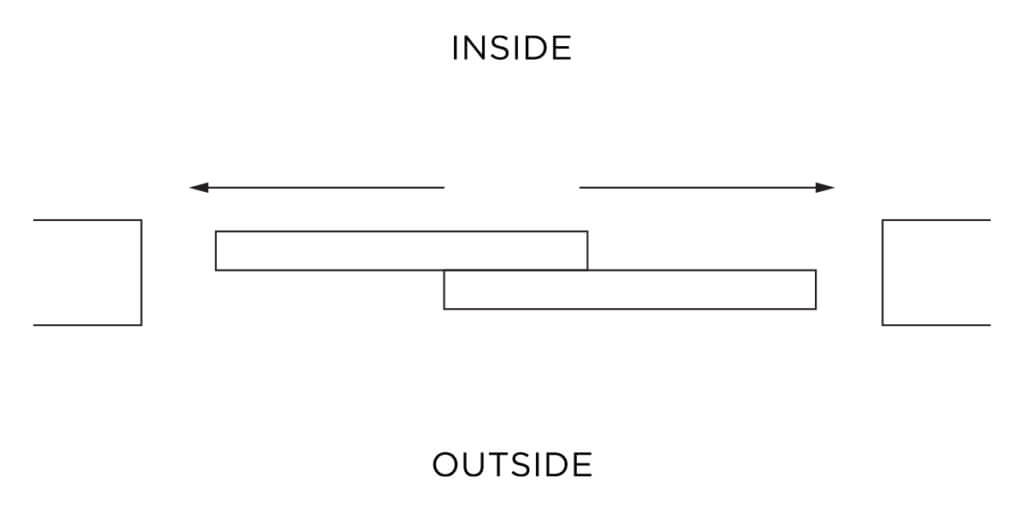

BALL CATCH, BYPASS, BI-FOLD DOORS

In addition to these handing and swing options, Sun Mountain offers interior double doors with “ball catch,” “bypass,” or “bi-fold” configurations. These double door options are most frequently used on closet or pantry door applications. For example, ball catches are typically used with “dummy” (non-active) handles on outswing closet doors. Ball catch hardware is provided and included in the price of ball catch doors. Track hardware is provided and included in the price of bypass and bi-fold doors. However, Sun Mountain does not bore for the dummy handles, knobs, or levers on these options. The following images illustrate these interior double door applications.

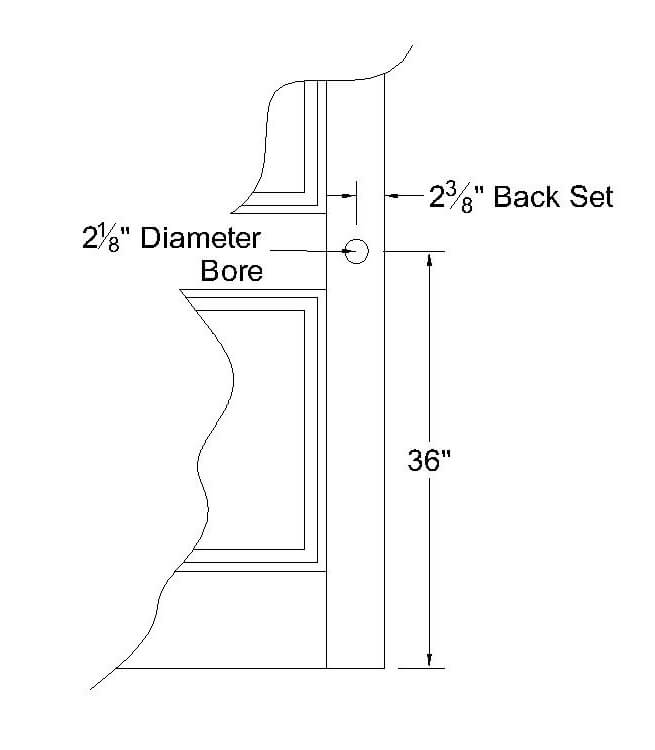

MACHINING FOR HARDWARE

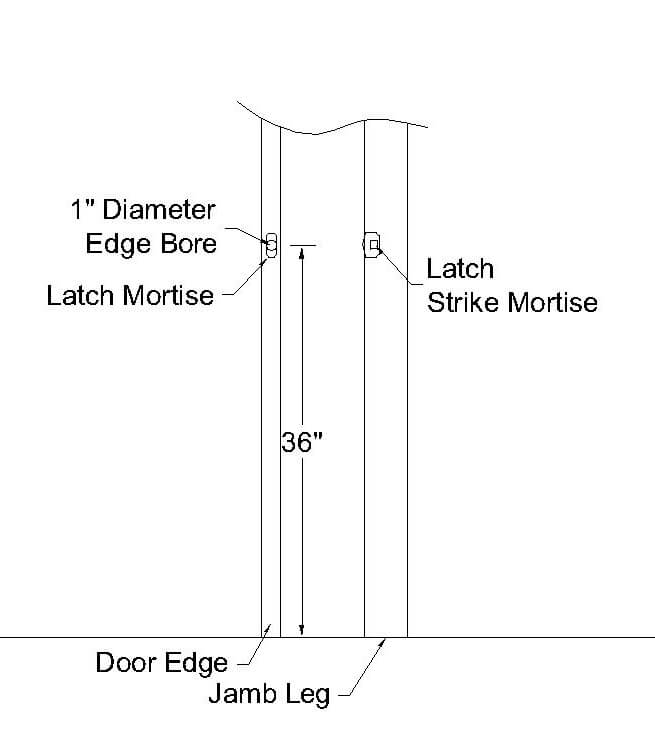

When a pre-hung door is ordered, Sun Mountain can bore and mortise the new door for a handle or lockset (called “machining”) at no additional charge. The machining must match the desired hardware for the door, and the customer must verify this with the hardware supplier prior to selecting the bore position. If door hardware is purchased from Sun Mountain, Sun Mountain can assist with this and ensure that proper machining is specified to match the hardware.

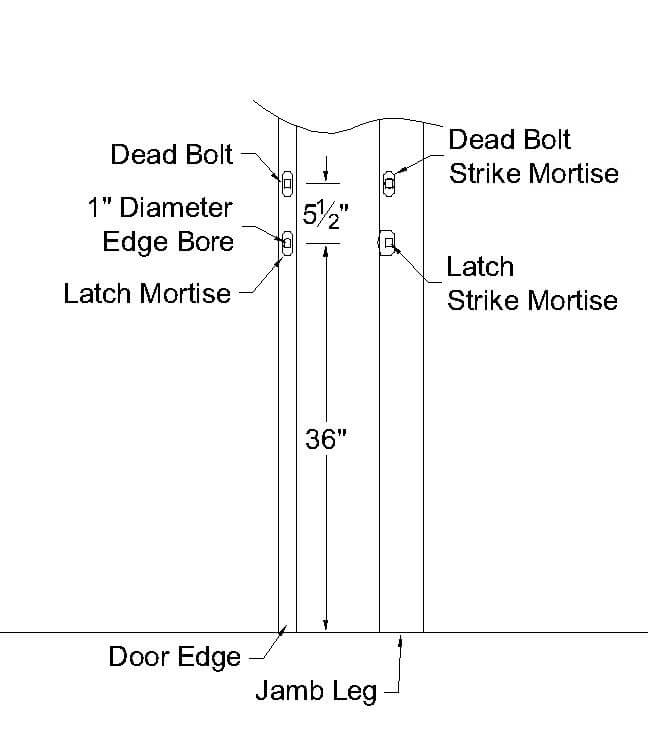

Both single bore and double bore machining options are available. Double bores are typically used on exterior doors, with both a lockset and deadbolt. Sun Mountain’s machining includes mortising the edge of the door for the latch (or both latch and deadbolt for double bore), and mortising the “strike” on the jamb leg (i.e., where the latch or deadbolt inserts).

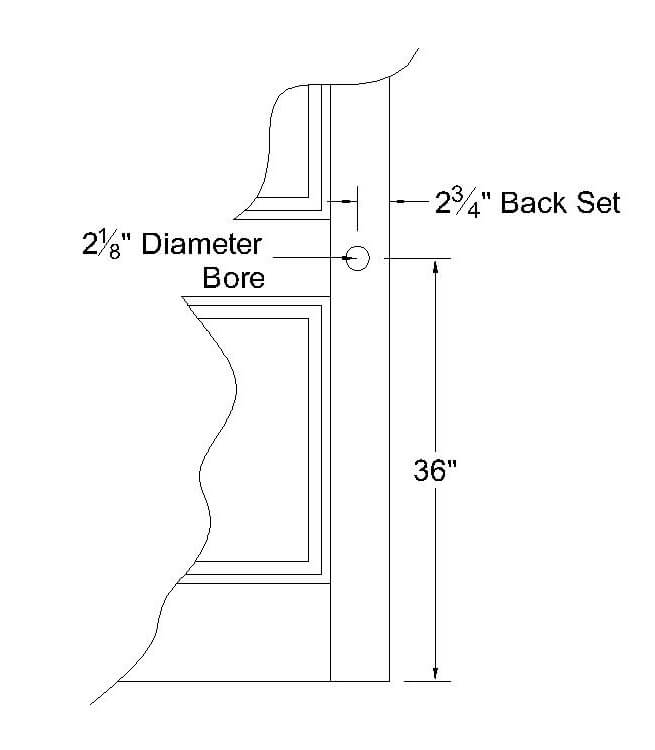

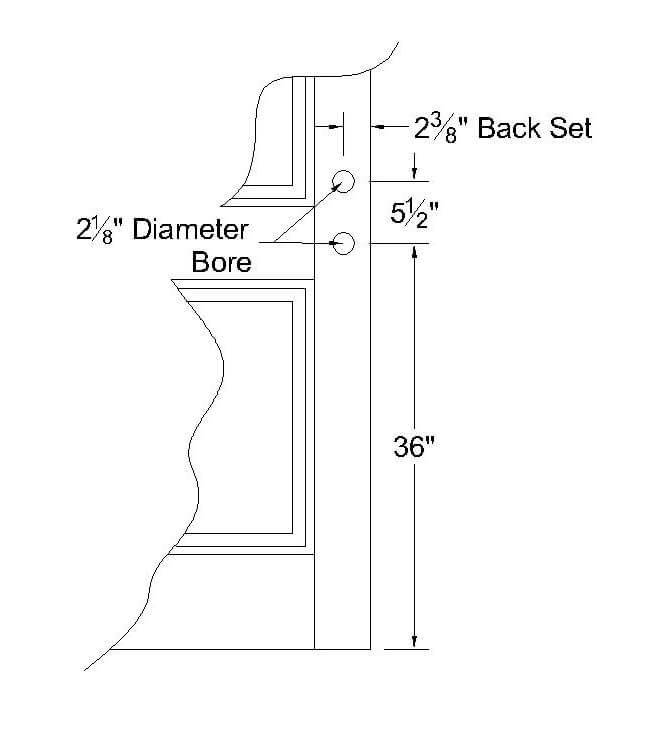

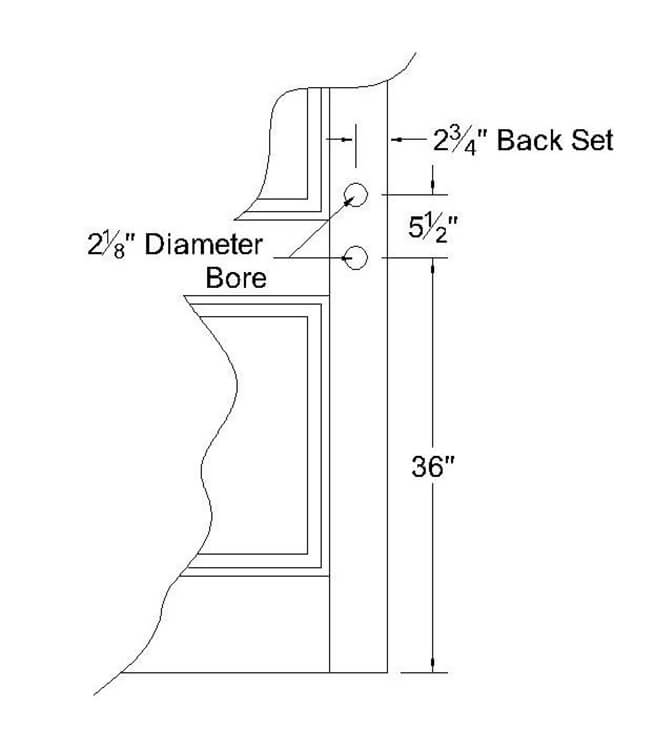

Sun Mountain’s standard machining for hardware includes the first bore at 36″ from the bottom of the door, and the bore hole diameter at 2-1/8″. For double bore options, the distance between the two bore holes is 5-1/2″ center to center (from the center of the diameter of one bore to the center of the diameter of the other bore). Available “backsets” (the distance from the edge of the door to the center of the bore diameter) are 2-3/8″ and 2-3/4″.

The following images illustrate Sun Mountain’s standard bore and backsets for both single bore and double bore.

HINGES

When a pre-hung door is ordered, high-quality square corner, ball bearing, pin and barrel hinges are provided at no additional charge. A choice of nine metal finishes are available (4″ hinges are shown here). Interior hinges are 4″ on all 1-3/4″ thick doors, and 4.5″ on all 2-1/4″ thick doors. Exterior door hinges are 4.5″ on all 1-3/4″ and 2-1/4″ thick doors. Sun Mountain determines the number of hinges required, based upon the size and weight of the door.

Additional hinge options are available, including custom pin and barrel hinges from suppliers such as Rocky Mountain Hardware®, Hagar®, and Emtek®, hidden hinges from SOSS® and Tectus®, and pivot hinges. These optional hardware items are available for an additional charge.

SHIPPING PRE-HUNG DOORS

All orders are shipped direct to the jobsite or business location in sturdy crating. Single door units are typically shipped pre-hung (as applicable), ready to install. Pre-hung double doors, arched top doors, doors with sidelites or transoms, and large-sized doors are shipped “knocked down” (or KD), and must be re-assembled prior to installation. Freight and crate charges apply and are calculated based on volume (door count).