DIY Information

Do It Yourself (or DIY) information includes the following topics:

Measuring Door Size

Measuring Jamb Width

Determining Handing and Swing

Determining Bore Position

Installing an Interior Door

Installing an Exterior Door

Measuring Door Size

The first step in measuring the size of a new door is to measure the rough opening where the door will be placed. Rough opening means the opening of the stud wall structure prior to installing the door jamb. The process for determining the door width and height needed for the rough opening is as follows:

- Measure the width of the rough opening, from inside of wall stud to inside of wall stud (see the illustration for this measurement). Measure this in three places—the top, middle, and bottom of the opening, and then use the smallest of these three measurements. Then, subtract 2″ from this width. This equals the needed door width. Example: Rough opening width = 38″. Door width needed = 36″, or 3′ 0″ (38″ – 2″ = 36″, or 3′ 0″)

- Measure the height of the rough opening, from the floor to the bottom of the upper stud of the opening (see the illustration for this measurement). Measure the height on both corner edges of the opening, and then use the smaller of these two measurements. Then, subtract 3″ from this height. This equals the needed door height. Example: Rough opening height = 99″. Door height needed = 96″, or 8′ 0″ (99” – 3” = 96″, or 8′ 0”)

If framing the rough opening for a new door (i.e., constructing the wall stud frame), reverse the measurements above. For example, select the desired finished door width and add 2″ to this measurement. Then select the desired finished door height and add 3″ to this measurement.

Why does the opening need to be larger than the door and its jamb? First, the additional space provides room to adjust the door and jamb to the rough opening. The stud wall structures of rough openings are not always plumb and square, so providing extra space allows the installer to “shim” the jamb for a perfectly plumb, level, and square door installation. Second, the additional height allows space for flooring material above the sub-floor such as carpeting, wood, or tile for interior doors, or the sill for exterior doors. Last, walls may expand and contract slightly with the natural humidity and moisture changes that occur with changing seasons. So the extra space allows for minor adjustments to the door fit, as necessary.

Measuring Jamb Width

Door jambs must cover the entire thickness of the wall where the door will be placed. Thus, the first step to choose the proper jamb width is to determine the thickness of the wall. Wall thickness includes the wall stud plus the sheetrock thickness. Normally, either 2×4 or 2×6 studs are used for wall framing. Sheetrock is usually either 1/2″ thick or 5/8″ thick (premium sheetrock). Determine the wall stud and sheetrock thickness and then use the charts below to select the proper jamb width to match the application.

Interior Jamb Widths

“Flat” jambs with adjustable stop are available for interior doors in the following widths, to match the following wall stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 4-5/8″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 4-7/8″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 6-5/8″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 6-7/8″ Wide |

A “kerf” is a slot cut on the edge of the jamb, used for wrapping the drywall corner bead (rounded drywall corners) into the jamb. Kerfed flat jambs provide for a “caseless” opening, with drywall connecting directly to the door fame, thus requiring no case mouldings. Kerfed (both sides) flat jambs for interior doors are available in the following widths, to match the following wall stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 3-1/2″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 3-1/2″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 5-1/2″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 5-1/2″ Wide |

Kerfed (one side) flat jambs for interior doors are available in the following widths, to match the following wall stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 4-1/16″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 4-3/16″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 6-1/16″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 6-3/16″ Wide |

Exterior Jamb Widths

“Rabbeted” jambs are required for exterior doors, and are more robust than flat jambs. These jambs include a non-adjustable stop cut into solid wood. Rabbeted jambs are available in the following widths, to match the following wall stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 4-5/8″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 4-7/8″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 6-5/8″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 6-7/8″ Wide |

Kerfed (one side) rabbeted jambs for exterior doors are available in the following widths, to match the following stud and sheetrock thicknesses:

| Stud, Sheetrock Thickness | Jamb Width |

|---|---|

| 2×4 Stud, 1/2″ Sheetrock | 4-1/16″ Wide |

| 2×4 Stud, 5/8″ Sheetrock | 4-3/16″ Wide |

| 2×6 Stud, 1/2″ Sheetrock | 6-1/16″ Wide |

| 2×6 Stud, 5/8″ Sheetrock | 6-3/16″ Wide |

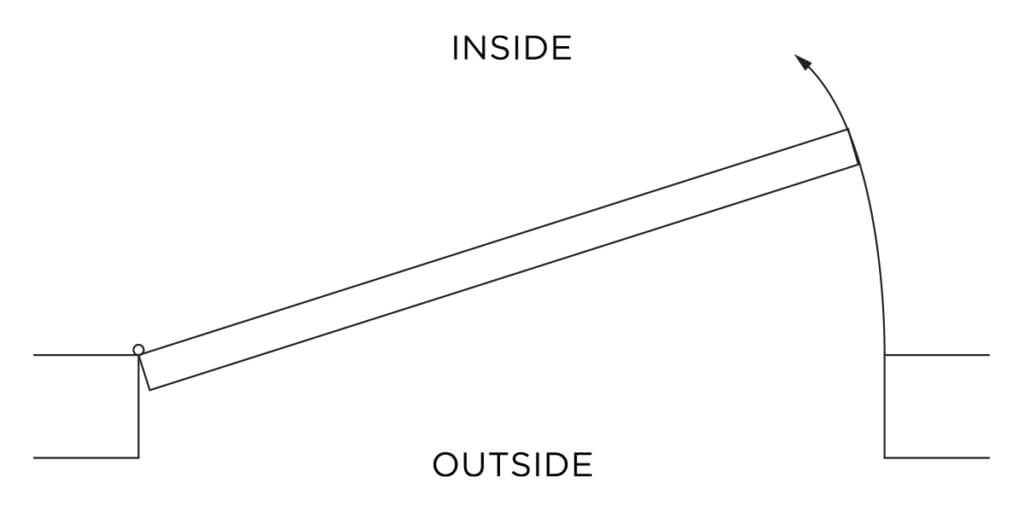

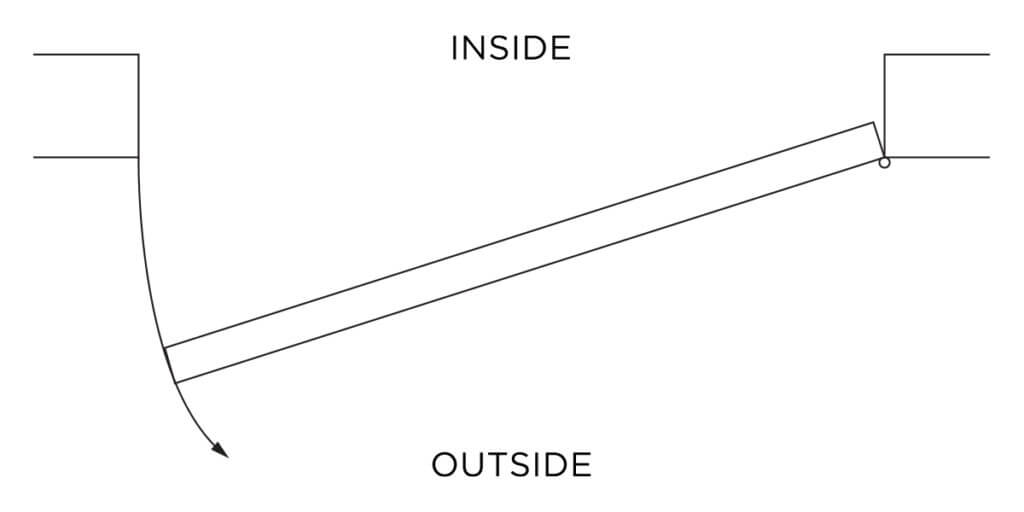

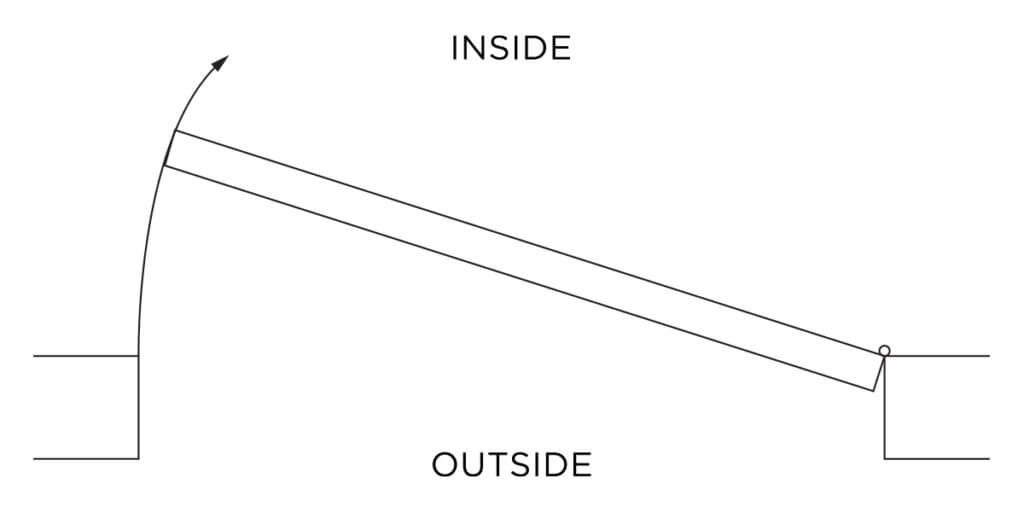

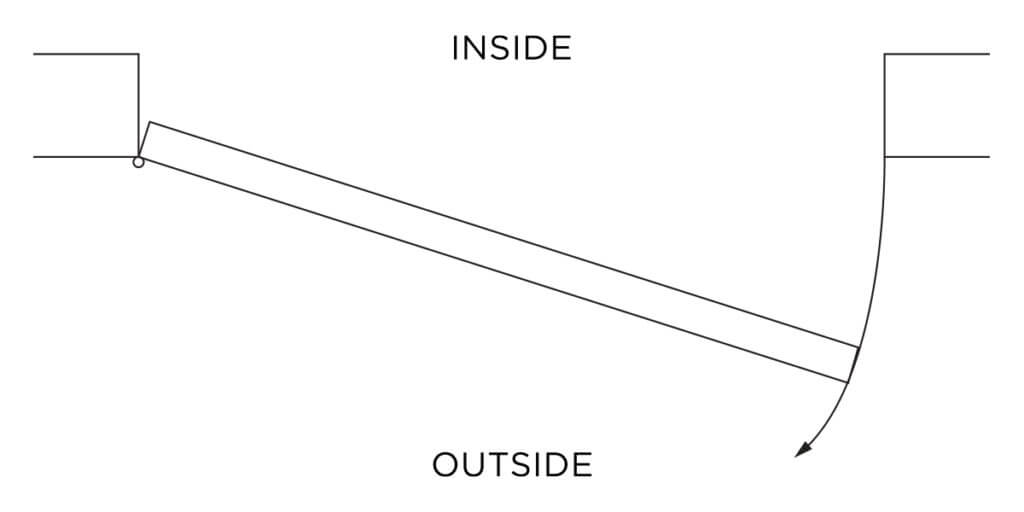

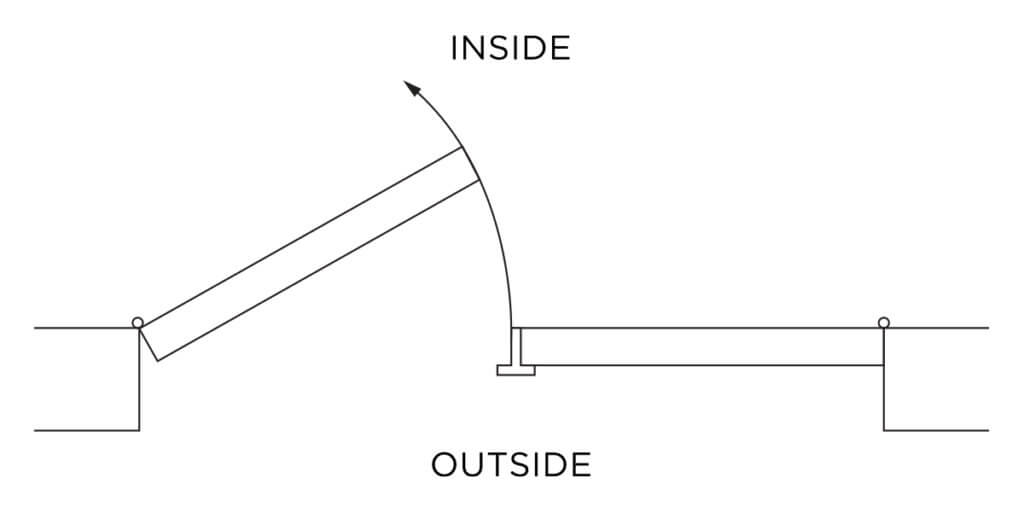

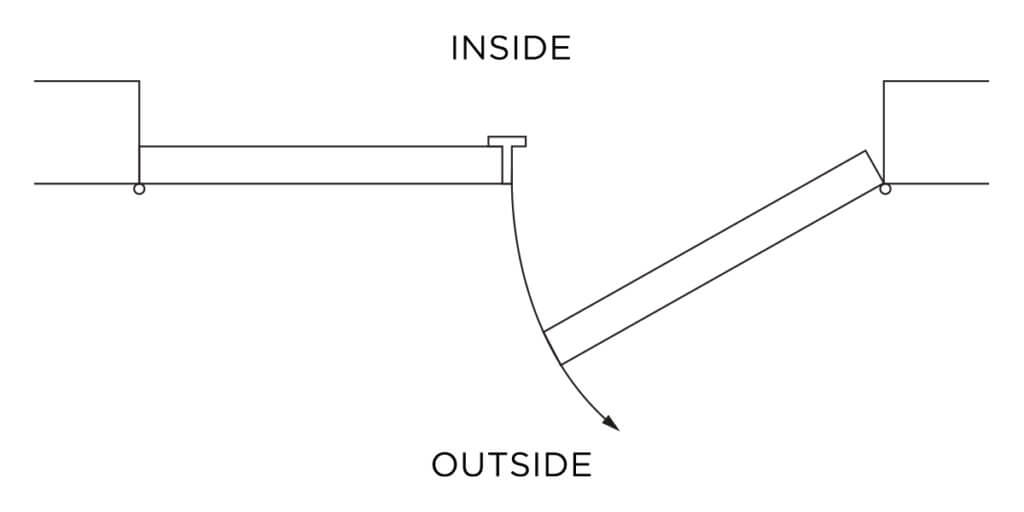

Determining Handing and Swing

“Handing and swing” refers to way the door opens—the side of the door that is hinged, and the way the door swings inside or outside of the room or home.

To determine door handing, a person stands in the doorway and positions his or her back against the jamb of the door where the hinges are to be placed. From this position, if the door is desired to open to the left, it is a “left hand” door. Or, from this position, if the door is desired to open to the right, it is a “right hand” door.

If the door is desired to swing inside the room or home, it is an “inswing” door. Or, if the door is desired to swing outside the room or home, it is an “outswing” door.

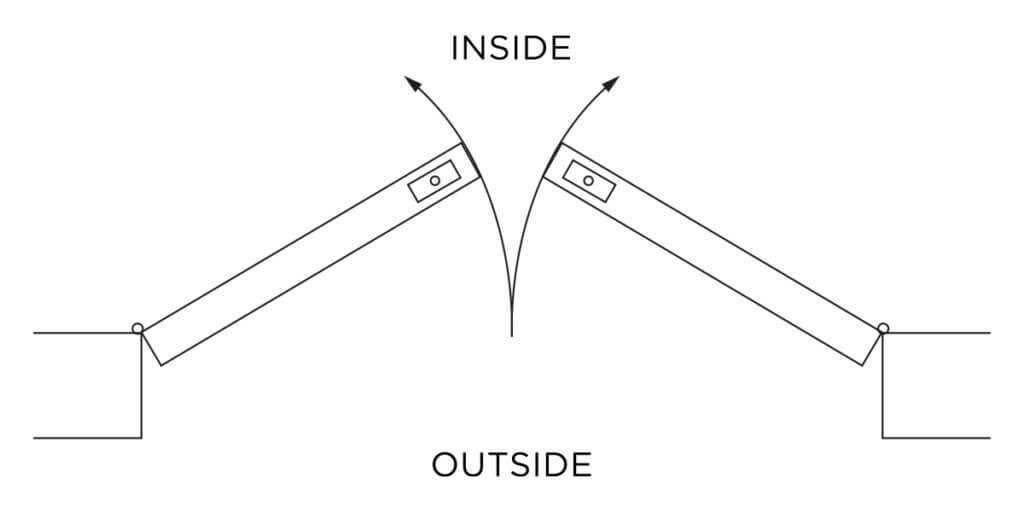

SINGLE DOORS

The following images identify handing and swing for single doors, either interior or exterior doors. Arrows point either inside (inswing) or outside (outswing) of the room or home, as denoted.

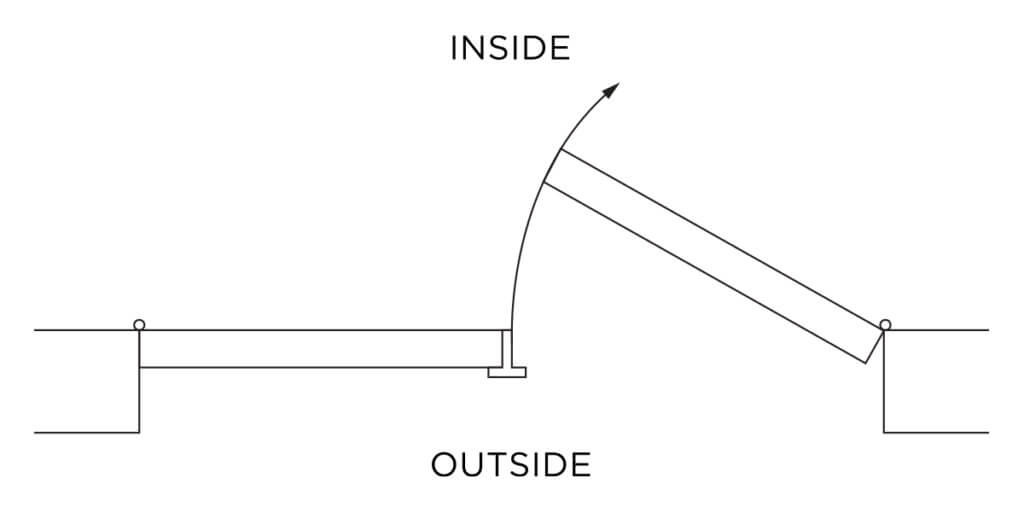

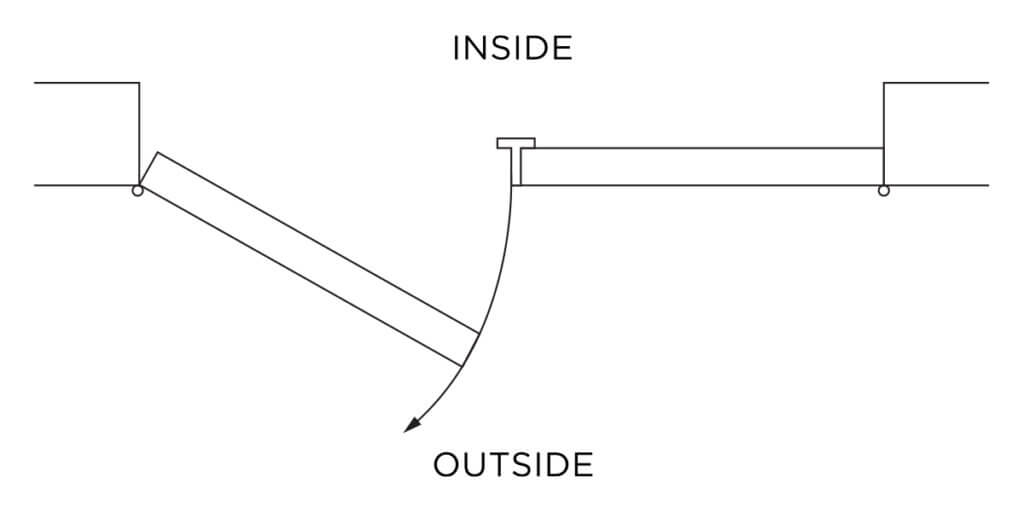

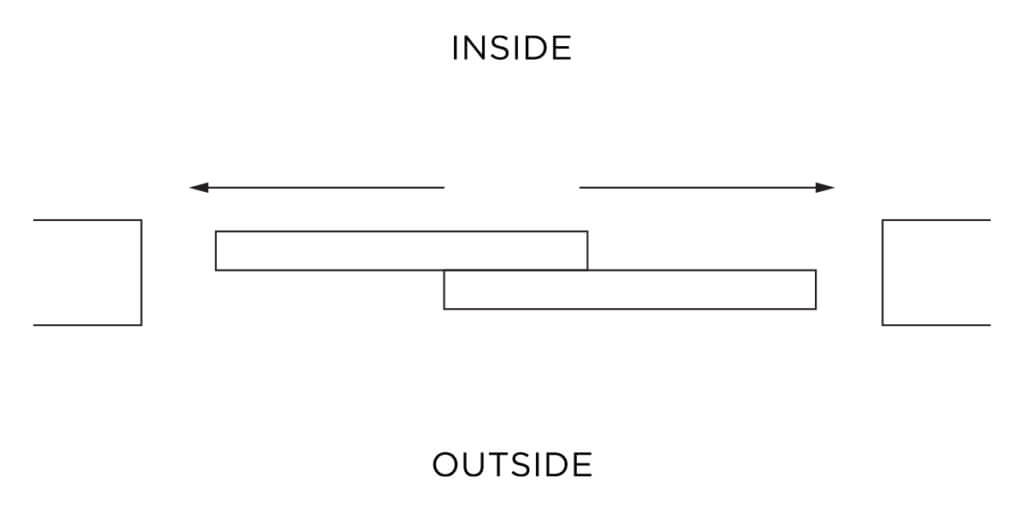

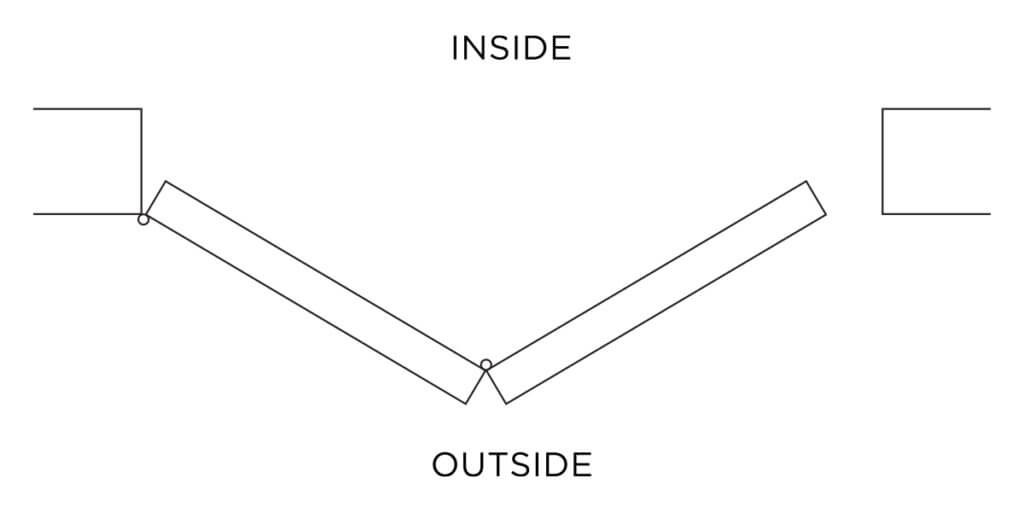

DOUBLE DOORS

For interior or exterior double doors, one door is designated as “active” (i.e., with an operating handle, knob, or lever to open the door), and the other door is designated as “inactive” (i.e., still opens and closes, but with no working handle, knob, or lever). The inactive door includes an attached “T-astragal,” providing a door stop for the active door. The inactive door also includes a “flush bolt,” to secure the inactive door in the closed position. Pre-hung interior double doors provided by Sun Mountain include a single flush bolt at the top of the inactive door. Pre-hung exterior double doors include flush bolts at both top and bottom of the inactive door.

The following images illustrate the side of the double door that is active, and the active door’s handing and swing. Arrows point either inside (inswing) or outside (outswing) of the room or home, as denoted.

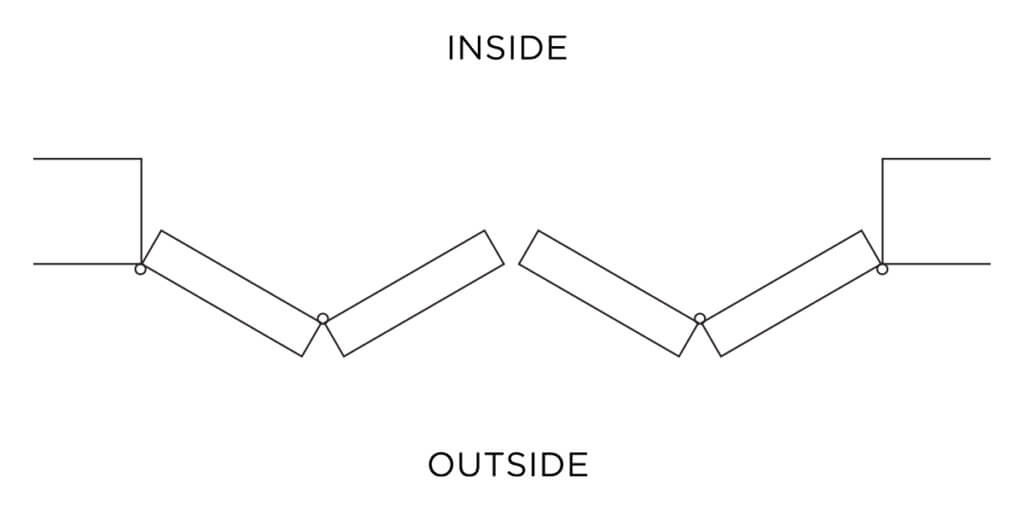

BALL CATCH, BYPASS, AND BI-FOLD DOORS

In addition to these handing and swing options, Sun Mountain offers interior double doors with “ball catch,” “bypass,” or “bi-fold” configurations. These double door options are most frequently used on closet or pantry door applications. For example, ball catches are typically used with “dummy” (non-active) handles on outswing closet doors. Ball catch hardware is provided and included in the price of ball catch doors. Track hardware is provided and included in the price of bypass and bi-fold doors. However, Sun Mountain does not bore for the dummy handles, knobs, or levers on these options. The following images illustrate these interior double door applications.

Determining Bore Position

When a pre-hung door is ordered, Sun Mountain can bore and mortise the new door for a handle or lockset (called “machining”) at no additional charge. The machining must match the desired hardware for the door, and the customer must verify this with the hardware supplier prior to selecting the bore position. If door hardware is purchased from Sun Mountain, Sun Mountain can assist with this and ensure that proper machining is specified to match the hardware.

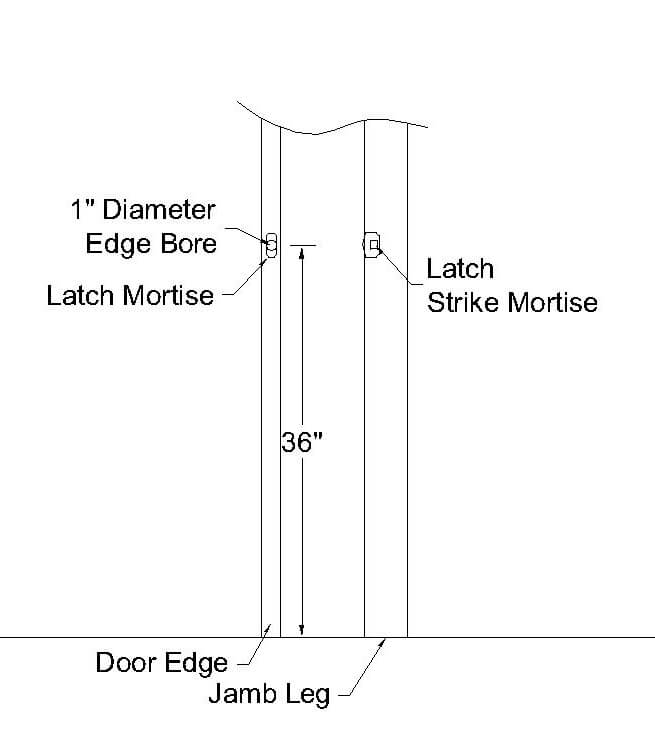

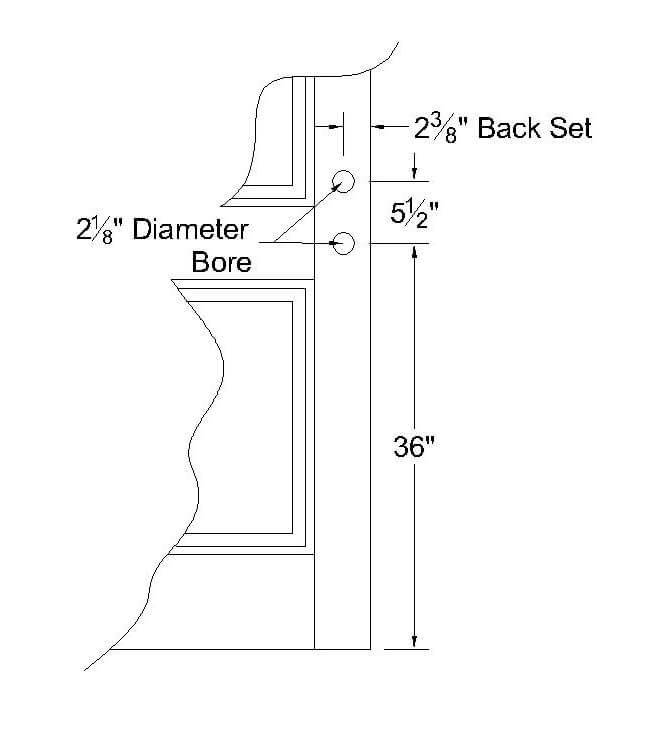

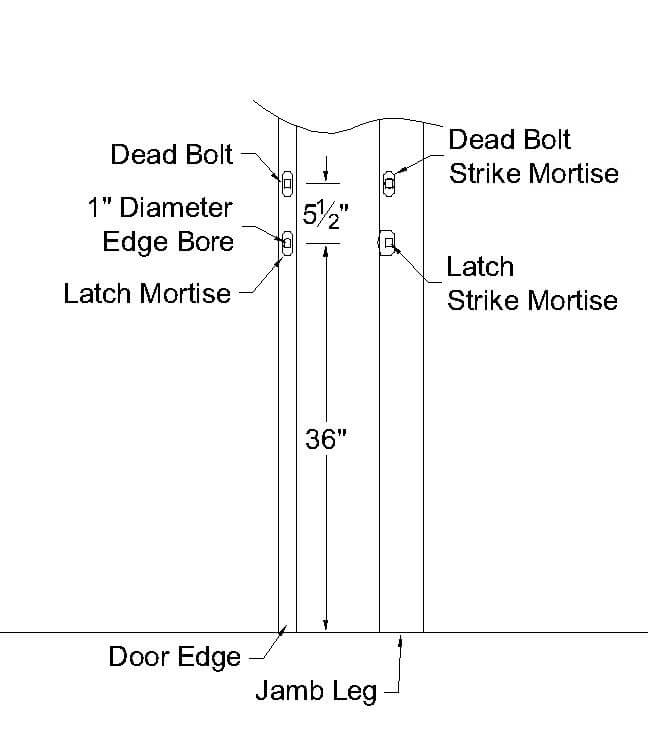

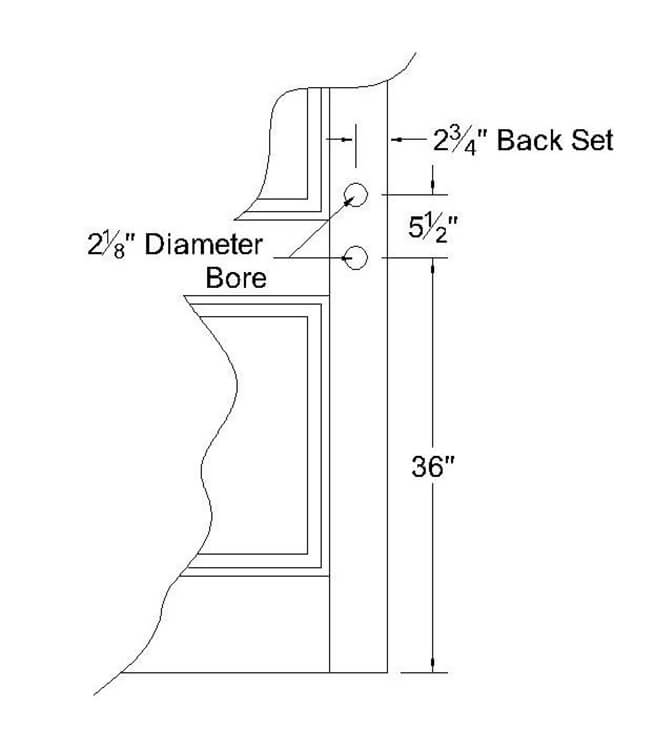

Both single bore and double bore machining options are available. Double bores are typically used on exterior doors, with both a lockset and deadbolt. Sun Mountain’s machining includes mortising the edge of the door for the latch (or both latch and dead bolt for double bore), and mortising the “strike” on the jamb leg (i.e., where the latch or deadbolt inserts).

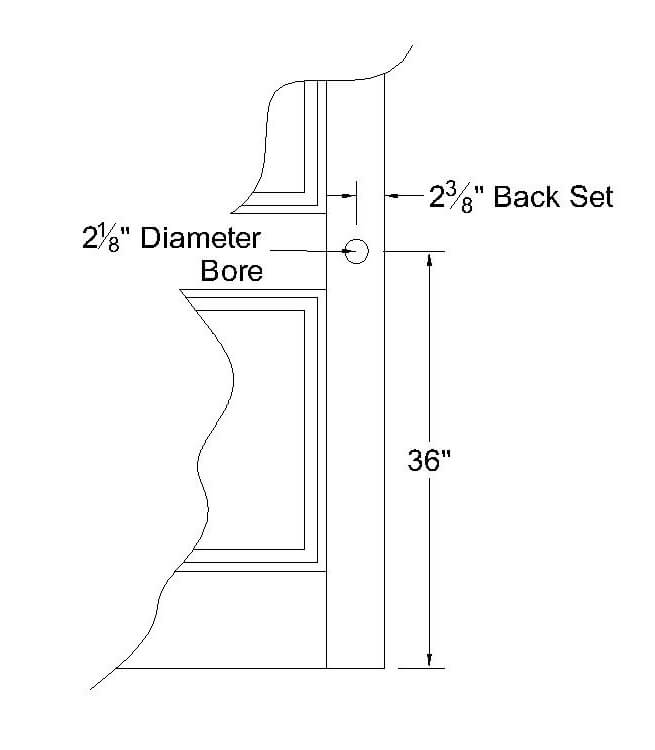

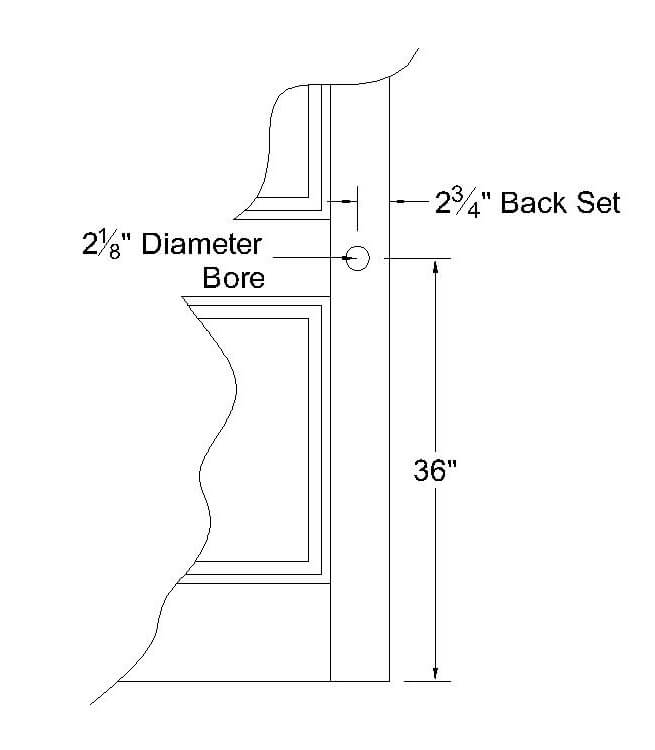

Sun Mountain’s standard machining for hardware includes the first bore at 36″ from the bottom of the door, and the bore hole diameter at 2-1/8″. For double bore options, the distance between the two bore holes is 5-1/2″ center to center (from the center of the diameter of one bore to the center of the diameter of the other bore). Available “backsets” (the distance from the edge of the door to the center of the bore diameter) are 2-3/8″ and 2-3/4″.

The following images illustrate Sun Mountain’s standard bore and backsets for both single bore and double bore.

Installing an Interior Door

Step-by-step instructions for installing a pre-hung and pre-finished interior door are provided in this section. Sun Mountain assumes no liability associated with following these instructions, and strongly suggests that do-it-yourselfers consult a professional contractor for door installation. The skill level for this installation is “Intermediate.”

Tools Required

6′ Level

Hammer

Drill

Tape Measure

Materials Required

Interior door, pre-hung and pre-finished

Shims

2-1/2″ Finishing Nails

2-1/2″ Screws

Step-by-Step Instructions

- Place the door and jamb unit in the opening. Position the pre-hung door unit in the rough opening. Center the unit so that equal spacing exists between the unit and the wall studs or wall structure on each side.

- Shim the hinge side of the door. Shims should be used to fill the open space between the door jamb and wall stud on the hinge side of the unit. Place shims between the door unit and wall stud at each hinge location.

- Temporarily secure the door in the opening. Ensure that the door unit is flush with the face of the sheet rock, front and back. Pre-drill a hole through the door stop at the top hinge shim (or, as desired, remove the adjustable stop and pre-drill through the jamb behind the stop). Nail one 2-1/2″ finishing nail in this hole to temporarily hold the door in place.

- Verify that the hinge side of the door is square and plumb. Using a 6′ level placed on the front face of the hinge side of the jamb, verify that the jamb is square. Adjust the middle and lower hinge shims until the bubble on the level is exactly in the center. After the hinge side of the jamb is square, check for plumb on the jamb. Rotate the level so it is sitting flat along the front edge of the hinge side of the jamb. Again ensure that the associated bubble on the level is exactly in the center.

- Secure the jamb on the hinge side. Once the hinge side of the jamb is square and plumb, pre-drill holes through the stop at both the center and bottom hinges (or, as desired, remove the adjustable stop and pre-drill through the jamb behind the stop). Nail 2-1/2″ finishing nails through these holes to secure the hinge side of the jamb in place.

- Shim the strike side of the door. Shim the strike side (latch side) of the door unit, placing shims at the top, center, and bottom of the unit between the jamb and wall stud.

- Verify the strike side of the door is square and plumb. Using a 6′ level placed on the face of the strike side of the jamb, verify that the jamb is square. Adjust the middle and lower strike side shims until the bubble on the level is exactly in the center. After the strike side of the jamb is square, check for plumb on the jamb. Rotate the level so it is sitting flat along the front facing edge of the strike side of the jamb. Again ensure that the associated bubble on the level is exactly in the center.

- Secure the jamb on the strike side. Once the strike side of the jamb is square and plumb, pre-drill holes through the stop at both the center and bottom of the strike side of the jamb (or, as desired, remove the adjustable stop and pre-drill through the jamb behind the stop). Nail 2-1/2″ finishing nails through these holes to secure the strike side of the jamb in place.

- Verify width measurements. Using the tape measure, verify that the distance between the hinge jamb and strike jamb is the same at the top, center, and bottom of the jamb. Carefully remove temporary nails and add or remove shims to adjust for equal distance at each position. Replace temporary nails after adjustment.

- Shim the header (top) of the jamb. Place shims in two equal positions on the top of the door unit, between the header (top) of the jamb and the wall stud above. Adjust the shims until an even margin (called the “reveal”) exists between the door and the jamb across the top of the door.

- Secure the jamb header (top). Pre-drill holes through the door stop in the location of each of the two shims on the header (top) of the unit (or, as desired, remove the adjustable stop and pre-drill through the jamb behind the stop). Nail 2-1/2″ finishing nails through these holes to secure the jamb header in place.

- Verify the reveal. Close the door and check to ensure that equal spacing exists between the door and jamb at the top and along both sides (again, called the reveal). Adjust shims at any position until equal spacing is achieved. (Replace all adjustable stop, as needed).

- Secure the unit with additional finishing nails. After verification of an even reveal, a second set of nails is needed to secure the jamb. Open the door and, on the hinge side of the jamb, place a second 2-1/2″ finishing nail next to the stop but on the narrow side of the jamb, for each of the three shim positions. Repeat this on the strike side of the door jamb. When all finishing nails have been installed, use a nail to counter sink the heads of all finishing nails.

- Replace center screws on the hinges. Once the second set of finishing nails are in place, remove the center hinge screw(s) from the top hinge where the hinge secures to the jamb (not where the hinge is attached to the door). Replace the screw(s) with a 2-1/2″ screw(s). Repeat this step on the center and bottom hinges (again, jamb side of the hinge only).

The interior door is now installed, and case moulding (if applicable) can be installed.

Installing an Exterior Door

For exterior door installation, Sun Mountain strongly suggests that do-it-yourselfers consult a professional contractor.